When selecting a laboratory countertop material, it’s essential to understand the chemicals, solvents, heat factors, reagents, fluids, and materials the lab uses. The type of chemical, biochemical, and biotechnology applications that take place in a lab require specific characteristics from countertops. In this article, we’ll look at the most common laboratory countertop materials and explore the pros and cons of each to help you make an informed decision for your laboratory design.

What Are Science Lab Countertops?

Laboratory countertops play a significant role in the research, discovery, testing, and development of laboratory work. The countertop surface is where the testing, sampling, and experimentation often happen. The countertop surface must meet the scientific workflow’s demands and withstand the heat, moisture, reagents, solvents, and corrosive materials used to process samples, materials, and testing. When it comes to science, time and accuracy matter, and an underperforming countertop can create unnecessary downtimes and safety issues.

How To Choose Science Lab Countertop Materials

There are many types of countertop materials that you can use in a scientific lab. The most important thing to understand is what will be happening in the lab and any exposure to potentially harmful materials or processes that could occur.

You will want to know if it’s a wet or dry lab or a high-heat environment. Are there highly corrosive materials and fluids in the lab? Additionally, you’ll want to consider other practicalities such as price, hygienic properties, maintenance, cleanability, durability, and lead times for materials.

Epoxy Resin Countertops

Epoxy countertops are the standard for most laboratories as they can resist high heat, open flames, and fire. Epoxy resin countertops are a great place to start, as they are incredibly versatile and customizable and can integrate nicely with sinks and other benchtop equipment. This type of countertop is frequently included with laboratory casework and industrial benchtops for its ability to resist heat, chemicals, and moisture. Epoxy resin is a heavy, durable, manufactured product made from a mixture of epoxy, silica, and other fillers that are molded and heated in an oven. The result is a flat, nonporous, hygienic surface that’s easy to clean, durable, and holds up to harsh chemicals and busy laboratory work environments.

While epoxy resin countertops are ideal for many labs, they have some drawbacks. The material is extremely heavy and expensive to ship and transport. It is also prone to scratches and can’t be exposed to UV-rays for long. Abrasive cleaners and scrubbing pads can also damage the countertop. Still, epoxy resin countertops can withstand chemicals, heat, solvents, bacteria, flames, and moisture, making them worth consideration.

Laminate Countertops

If you’re considering laminate for your laboratory countertop, specify a chemically resistant, high-pressure laminate. This type of laminate includes a melamine resin over the decorative surface area to provide additional functionality, durability, and chemical resistance. Still, you’ll need to be sure the countertop can withstand the solvents and chemicals used in the lab without causing damage. If you don’t need to worry about chemical exposure, an inexpensive high-pressure laminate may be all you need.

On the plus side, chemically-resistant laminate countertops come in various designs and colors for a cohesive and professional look. They can also withstand heat up to about 275°F for brief periods. They also offer a mid-range price point, making them more affordable than some other materials.

Unfortunately, laminate isn’t as hygienic or durable as epoxy resin or other materials. It can absorb moisture and become a breeding ground for bacteria, molds, fungi, and other contaminants. It can also chip and scratch/cut easily. Using this countertop away from high heat and chemicals is the best use of this material.

Phenolic Resin Countertops

Like epoxy resin countertops, phenolic resin is a durable, nonporous material that can resist many chemicals. With phenolic resin countertops, the kraft paper layers that make up the material are saturated in a phenolic resin before being finished with high heat and pressure. Phenolic resin countertops are lightweight, long-lasting, and durable, with the ability to resist many chemicals and solvents used in science labs. However, some caustic chemicals may cause damage to phenolic resin countertops.

Phenolic resin countertops also resist bacteria and moisture and can withstand heat exposure up to 350°F. The main difference between epoxy resin and phenolic resin countertops is that phenolic resin countertops aren’t flame retardant. Phenolic resin countertops are flammable, and excessive heat exposure may burn through the surface layers of the material.

Phenolic resin is a smart and viable option if you’re looking for a hygienic, strong, easy-to-clean countertop or worktop. Phenolic resin can be used in healthcare, science, and pharmaceutical labs, where top priorities are bacterial, fungal, moisture, and chemical resistance. This countertop material will last for many years, is impact and scratch-resistant, and comes in various colors. It’s also more affordable than many other materials.

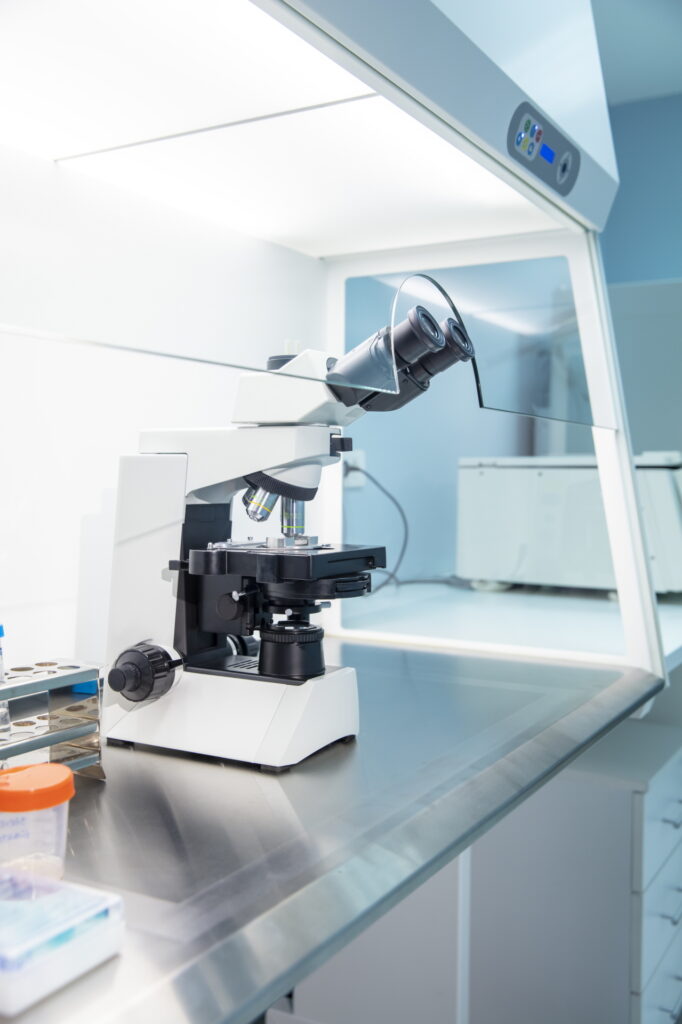

Stainless Steel Countertops

Stainless steel is a popular laboratory material, from benchtops to countertops. Stainless steel is a premium material option that performs well in many laboratory settings. Most stainless steel contains chromium, which hardens and toughens the material and makes it resistant to corrosion at high temperatures. Stainless steel also includes nickel which makes it naturally heat resistant.

Additionally, stainless steel is nonporous and easy to sanitize. Liquids, solvents, and fluids won’t penetrate the surface, and bacteria, mold, and germs won’t stand a chance with stainless steel. Stainless steel can withstand heat up to 1500°F, but prolonged high-heat exposure may cause some discoloration.

Stainless steel can scratch and dent if you aren’t careful. Stainless steel counters also come with a high price tag. However, stainless steel is often more affordable than epoxy resin countertops.

Which Countertop Material Is Best for a Science Lab?

When selecting countertop material for any science lab, there isn’t one material that stands out as a clear winner. It all depends on the lab and its needs. Understanding what happens in the lab and the types of solvents, fluids, and chemicals used in the space can help you identify what materials to use. If there’s a lot of moisture or heat, that will also affect the decision.

Like any capital investment or improvement, countertop decisions should be made based on current activities and future plans. Does the laboratory plan to take on new research or diversify its applications? The more you know about the science that takes place or will take place in the lab, the better you, as a designer, will be able to make a strong recommendation.

Contact Us

Let’s talk about your next design project. Please visit our website and fill out a brief form about your project. One of the LX Hausys countertop experts will respond promptly. Responses will be sent to the email provided on the form.